Swagelok Reference Point

Your resource for practical advice to achieve more with your fluid systems.

Explore Blog CategoriesInternet Explorer 8 or 9 is not supported by this website. Please use a more up to date browser.

Swagelok Reference Point provides industrial professionals with insights and analysis intended to help decrease downtime, increase efficiencies, troubleshoot issues, and maintain a safe workplace staffed by effective associates. Browse our latest blog posts below to learn how you might more easily accomplish your fluid system-related goals.

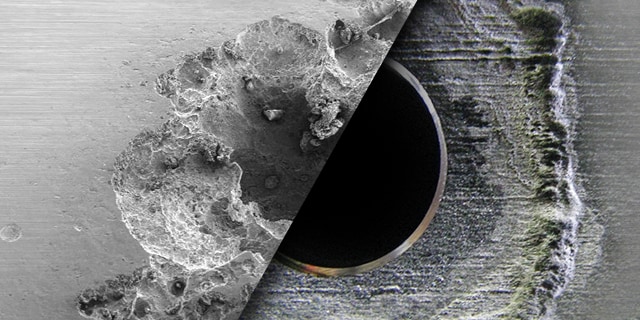

Stainless steel corrosion is a major challenge for oil and gas operators everywhere, but it can be prevented. Learn how to identify the differences between pitting corrosion and crevice corrosion.

Learn more about trends affecting fluid systems operators and get advice from our team for responding to the trends to minimize the impact to your business.

Have questions about the sustainability profile of hydrogen fuel? We have answers—learn more about hydrogen production and the fuel’s potential as a viable, sustainable power source.

Is hydrogen too expensive for mass adoption as an alternative fuel? The answer is simple: No. Learn why hydrogen fuel prices continue to fall, making it a viable alternative to fossil fuels.

Do hydrogen fuel cell vehicles have what it takes to travel comparable ranges to gasoline or diesel vehicles? We have the facts. Learn why hydrogen is a viable fuel for longer-range travel.

Learn about safe and effective liquid grab sampling techniques, as well as ideal design characteristics to seek out when selecting and specifying your systems and panels.

Hydrogen has the potential to be a revolutionary clean energy source, but some common myths abound about the fuel’s safety. Get the facts about hydrogen as we explore why it’s a safer fuel source than conventional options.

Selecting the right materials for hydrogen-handling applications is critical to the long-term viability of hydrogen as a fuel source. Learn how to select the right materials and prevent hydrogen embrittlement.

Refineries and oil and gas facilities face an increasing need to reduce fugitive emissions throughout their facility. Learn the driving factors behind decarbonization and fugitive emissions reduction and strategies to do it.

Learn how to apply the practical STAMPED method to select the valves most suited to your industrial fluid or sampling system design applications.

Learn the differences between common types of pressure regulators for industrial fluid and analytical systems, as well as how to choose a regulator most appropriate for your system needs.

Learn why intermixing or interchanging tube fitting components from different manufacturers can lead to poor fluid system performance.

To receive updates on our latest posts, be sure to follow us on LinkedIn

Search by industry or application to find more posts written with your challenges in mind