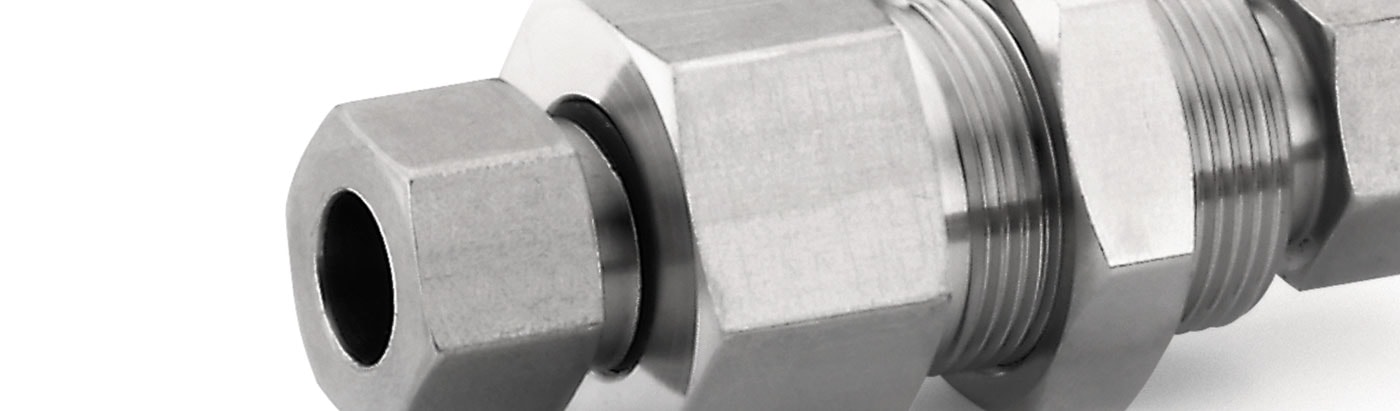

Swagelok® Medium-Pressure Tube Fittings (FK Series)

The two-piece design of Swagelok® FK series medium-pressure tube fittings reduces installation time and lowers maintenance costs. These fittings provide a vibration-resistant, leak-tight, and robust connection that protects workers and the environment.

FK series fittings have revolutionized fluid connections in downhole oil and gas exploration applications and streamlined R&D fluid systems requiring frequent reconfiguration. These fittings also aided in the development of the hydrogen economy through leak-tight hydrogen fluid connections that meet the requirements of EC-79 for performance at pressures up to 700 bar [10 150 psig] in hydrogen applications.

Read about four qualities to look for in fittings for hydrogen fuel cell technology

The design of Swagelok FK series fittings consists of a female fitting body and a preassembled cartridge containing the male nut and color-coded front and back ferrules on a disposable arbor. The preassembled cartridge ensures correct ferrule orientation, visual confirmation of ferrule presence, and proper installation into the female body. These fittings are available in 316 stainless steel, alloy 2507, and alloy 625. The body/cartridge combination allows for easy installation using either specified turns or torque using standard tools.

Learn How to Assemble FK Series Medium-Pressure Tube Fittings

Medium-Pressure Tube Fittings Catalogs

The strain-hardened 316 stainless steel FK fitting bodies are available in straight, elbow, and tee shapes to meet your configuration needs in a lightweight, space-saving design. Find detailed product information, including materials of construction, pressure and temperature ratings, options, accessories, and installation instructions in the product literature provided here.

FK and IPT Series Products Cone and thread or medium-pressure tube fitting connections Excellent corrosion resistance in chloride-containing environmentsManufactured to meet NORSOK and NACE® MR0175/ISO15156

Swagelok® offers medium- and high-pressure fittings, tubing, valves, and related accessories with temperatures up 1000°F (537°C), pressure ratings up to 60 000 psig (4134 bar) in sizes ranging from 1/4 to to 1 in. for medium-pressure products and 1/4 to 9/16 in. for high-pressure products. NACE® MR0175/ISO15156 compliance is available.

Tube Fittings Comparison (FK Series)

Watch and compare installation of FK series and cone and thread fittings.

Compare the FittingsSwagelok Resources Curated for You

AGI Industries

Read how Swagelok helped AGI Industries achieve leak-free performance at 15 000 psi for 13 500 potential leak points with Swagelok FK series valves and fittings.

Optimizing Component Selection for Hydrogen Fuel Cell Vehicles

Hydrogen transportation depends on reliable component specification and selection.

Case Study: Offshore Oil Operator

Read how Swagelok helped an offshore oil operator reduce installation labor time and enhance overall performance by changing existing cone and thread connections with Swagelok's FK series fittings.

Empa and Swagelok’s Collaborative Research Fuels Development of Hydrogen Transportation Innovations

The Swiss Federal Laboratories for Materials Science and Technology (Empa) and Swagelok are exploring the viability of hydrogen-based transportation solutions. One recent research breakthrough stemming from our collaboration incorporated Swagelok’s FK series fittings within the Empa hydrogen solution. Using FK series fittings instead of traditional Swagelok tube fittings significantly eased installation, while improving leak-tightness, reliability, and safety.

FK Series Medium-Pressure Tube Fittings

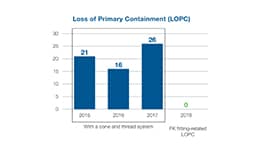

From initial construction and commissioning through daily operations and maintenance, there is a tremendous focus on reducing total lifecycle costs. FK series tube fittings can reduce maintenance costs and provide high reliability, reducing system downtime, when proper assembly processes are followed. These fittings can also help mitigate environmental impact via leak reduction as well as improve overall safety by protecting your system against corrosion.

Read about how to build more productive critical fluid systems with FK series fittings